Selecting the right LED work light for industrial environments requires more than comparing lumen outputs. Professional users need equipment that performs reliably under demanding conditions, withstands rough handling, and delivers consistent illumination throughout extended shifts. The wrong choice leads to inadequate lighting, premature failures, and avoidable equipment replacement costs.

This guide covers the key specifications and features that distinguish industrial-grade LED work lights from consumer alternatives. Whether you’re equipping maintenance teams, outfitting inspection crews, or specifying lighting for construction operations, understanding these factors helps ensure your investment delivers genuine operational value.

Why LED Technology Suits Industrial Applications

LED technology has transformed industrial lighting over the past decade. Compared to halogen and incandescent alternatives, LED work lights offer significantly longer operational life, reduced power consumption, and lower heat output. These characteristics translate directly into practical benefits for professional users.

Energy efficiency matters when equipment runs for full shifts. A rechargeable LED work light consuming less power per lumen delivers longer runtime from the same battery capacity. This extended operation reduces the need for mid-shift charging or battery swaps, keeping crews productive without interruption.

Durability improves because LEDs contain no fragile filaments. The solid-state construction withstands vibration and impact that would destroy traditional bulbs. For work environments involving heavy machinery, vehicle movement, or rough handling, this resilience prevents the frustration of frequently replacing damaged lights.

Heat management also improves safety. LED work lights produce far less radiated heat than halogen equivalents, reducing burn risks when lights are handled during operation and minimising fire hazards in environments with combustible materials.

Lumen Output and Beam Characteristics

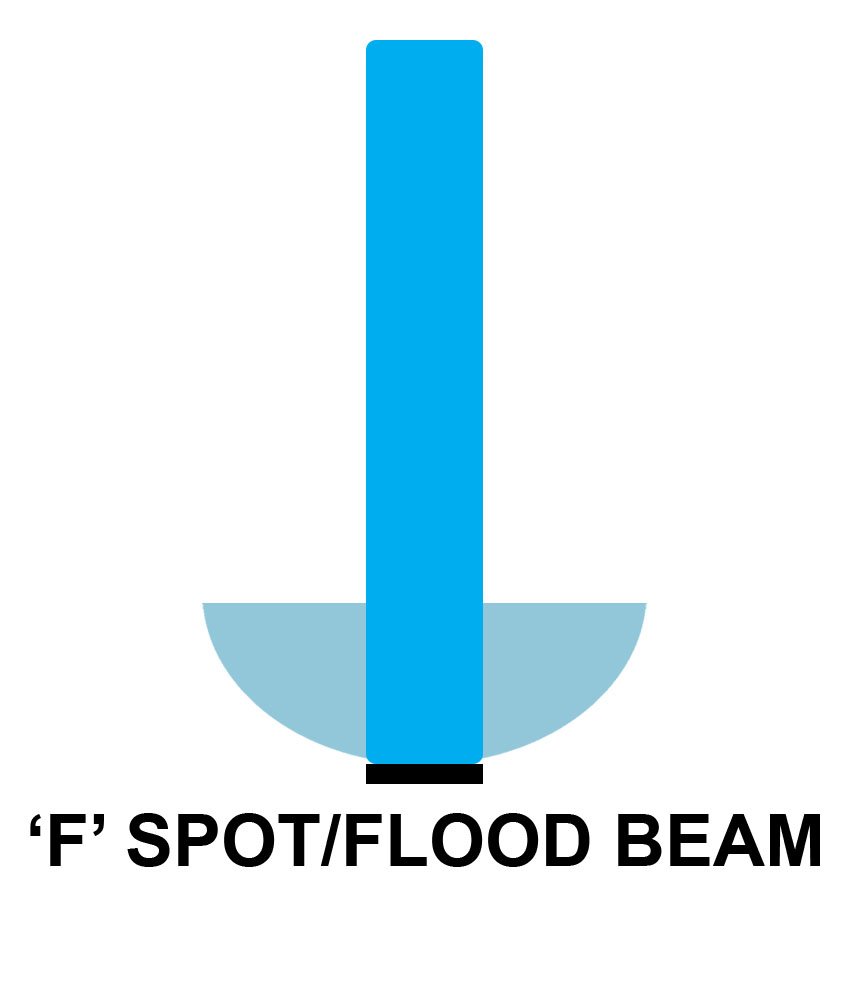

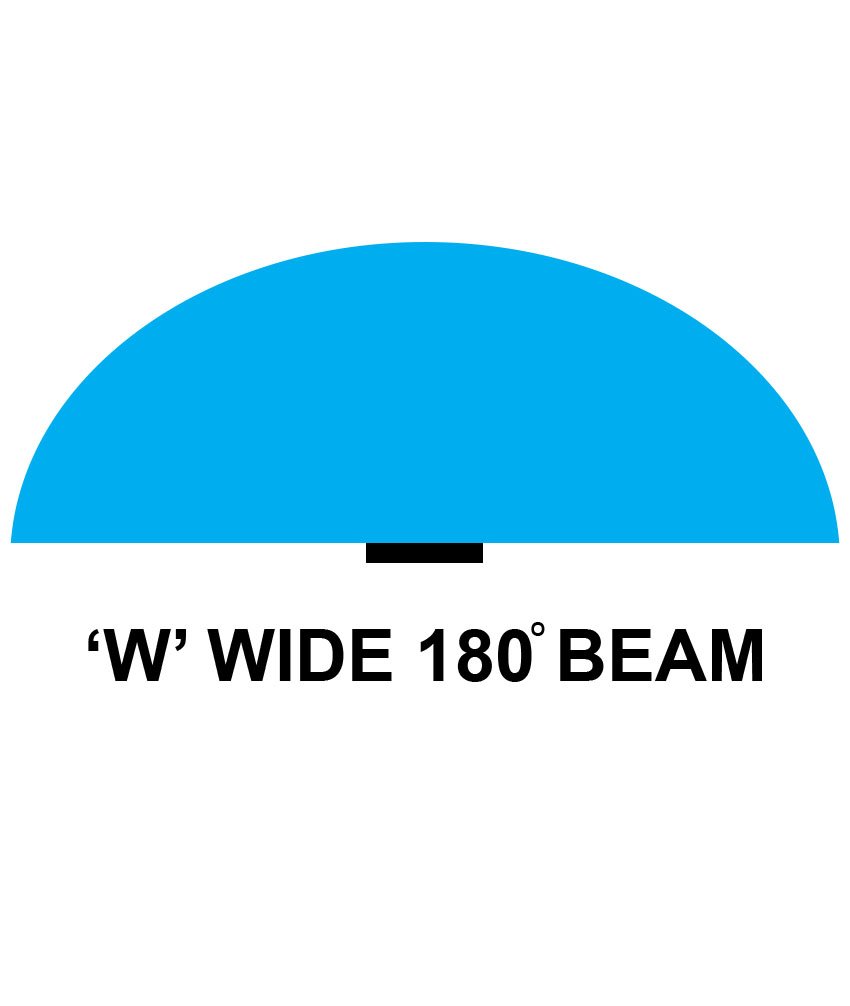

Raw lumen figures provide only part of the picture. A high lumen count means nothing if the beam pattern doesn’t suit your application. Industrial LED lighting should match the task: broad flood patterns for general area illumination, focused spots for detailed inspection work, or adjustable beams for versatile deployment.

Beam Type Comparison

| Flood Beam | Spot Beam |

| Wide coverage area General workspace illumination Equipment staging areas Site perimeter lighting | Concentrated, focused light Detailed inspection tasks Electrical and wiring work Component examination |

Consider where the light needs to reach. Portable floodlights work well for illuminating work zones, equipment staging areas, and general site coverage. Focused beams suit inspection tasks, electrical work, and situations requiring concentrated light on specific components.

Colour temperature affects visual clarity and task performance. Most industrial LED work lights produce light in the 5000K to 6500K range, approximating daylight. This colour temperature supports accurate colour perception, which matters for tasks like identifying wire colours, inspecting welds, or assessing surface conditions.

Colour Rendering Index (CRI) indicates how accurately colours appear under the light source. Higher CRI values (80+) enable more reliable visual assessment. For quality inspection, maintenance diagnostics, or any task where colour differentiation matters, prioritise lights with good CRI performance.

Battery Technology and Runtime

For rechargeable work lights, battery specification significantly affects practical usability. Lithium-ion and lithium iron phosphate (LiFePO4) batteries dominate professional equipment due to their energy density, cycle life, and consistent voltage delivery throughout discharge.

Runtime claims require careful interpretation. Manufacturers typically quote maximum runtime at lowest brightness settings. Evaluate runtime at the output levels you’ll actually use. A light offering 20 hours on low but only 3 hours on high may not suit applications requiring sustained bright illumination.

Charge time matters for operational planning. Fast-charging capability allows lights to be recharged during breaks or between shifts. Some units support charging while in use, maintaining illumination during the charging process.

Battery longevity over the equipment’s life affects total cost of ownership. Quality cells maintain capacity through hundreds of charge cycles. Cheaper batteries degrade quickly, reducing runtime and eventually requiring replacement. Units with user-replaceable batteries offer flexibility for extending equipment life.

Build Quality and Ingress Protection

Industrial environments expose equipment to conditions that quickly destroy consumer-grade products. Dust, moisture, impact, and temperature extremes all challenge lighting equipment. Specifications like IP ratings provide standardised measures of environmental resistance.

IP ratings consist of two digits. The first indicates dust protection (0-6), the second indicates water resistance (0-9). For most industrial applications, IP65 or higher ensures reliable operation. IP65 means complete dust protection and resistance to water jets from any direction. IP67 adds brief immersion capability.

Housing materials determine impact resistance and longevity. Aluminium construction offers excellent durability with reasonable weight. Reinforced polymers provide lighter alternatives with good impact absorption. Avoid lights with thin plastic housings that crack under stress.

Lens quality affects both light transmission and durability. Polycarbonate lenses resist impact better than glass while maintaining optical clarity. Look for scratch-resistant coatings that preserve light output over time.

Mounting Options and Positioning Flexibility

How a light can be positioned determines its practical versatility. Industrial work rarely happens in convenient locations. The ability to mount, hang, or stand a light exactly where needed directly impacts task effectiveness.

Magnetic bases allow instant attachment to steel structures, vehicles, and machinery. Strong magnets hold lights securely on vertical and overhead surfaces, freeing hands for work. Check magnet strength ratings to ensure secure attachment on the surfaces you’ll encounter.

Tripod and stand compatibility extends positioning options. Lights with standard mounting threads can attach to adjustable stands for precise height and angle control. For larger workspaces, dedicated area lighting systems with integrated stands provide stable elevated illumination.

Hanging hooks and carabiner attachments suit overhead positioning from scaffolding, cable trays, or structural elements. Rotating hooks allow angle adjustment after hanging.

For hands-free personal lighting, rechargeable head torches complement fixed work lights by providing directed illumination that follows the user’s line of sight. This combination suits tasks requiring both ambient workspace lighting and focused task illumination.

Controls and Operational Features

User interface design affects daily usability. Controls should be accessible while wearing work gloves and intuitive enough to operate without consulting instructions. Simple, tactile switches outperform complex multi-button interfaces for most industrial applications.

Key Features to Look For

| ✓ Glove-friendly controls | ✓ Multiple brightness levels |

| ✓ Battery level indicator | ✓ Memory function |

| ✓ Low-battery warning | ✓ Intuitive single-button operation |

Multiple brightness levels allow adaptation to different tasks and conservation of battery when full output isn’t required. Three to five levels typically provide sufficient flexibility without unnecessary complexity.

Battery level indication prevents unexpected shutdowns. Clear visual indicators showing remaining charge help users plan charging and avoid being caught without light. Some units offer audible low-battery warnings as additional protection.

Memory functions that recall the last-used brightness setting speed up deployment. Lights that always start on the highest or lowest setting require adjustment at every use.

Portability and Weight Considerations

The relationship between output and portability requires careful balance. Higher capacity batteries and larger LED arrays deliver more light but increase weight. Consider how often equipment will be carried and over what distances.

Inspection teams moving between multiple locations throughout a shift benefit from ultralight portable units that won’t cause fatigue. Static work positions can accommodate heavier, higher-output lights that remain in place for extended periods.

Carrying solutions matter for portable work lights. Integrated handles, shoulder straps, or belt clips make transport easier. Equipment cases protect lights during vehicle transport and storage.

Consider the trade-off between having one high-output light versus multiple smaller units. Distributing lighting across several positions often provides better coverage with less shadow than a single powerful source.

Safety Certifications and Compliance

Certain industries and environments mandate specific certifications for electrical equipment. Understanding relevant standards ensures selected equipment meets regulatory requirements and site access conditions.

ATEX certification indicates suitability for potentially explosive atmospheres. Petrochemical facilities, grain handling operations, and similar environments require lighting equipment rated for the specific hazard zone. Using non-certified equipment in these areas creates serious safety and compliance risks.

CE marking confirms compliance with European safety directives. This baseline certification should be present on any equipment used professionally within the UK and EU. Additional certifications like UKCA (UK Conformity Assessed) may apply depending on your operating jurisdiction.

Railway and utilities sectors often maintain approved equipment lists. Verify that selected lighting meets the specific requirements of environments where your teams operate. Non-compliant equipment may be prohibited from site, regardless of its technical capability.

Evaluating Total Cost of Ownership

Purchase price represents only part of the lifetime cost of industrial lighting equipment. Professional users should evaluate total cost of ownership, including energy consumption, maintenance requirements, replacement cycles, and operational efficiency impacts.

Rechargeable LED work lights eliminate ongoing battery or fuel costs associated with disposable-battery or generator-powered alternatives. Over equipment lifespans measured in years, these savings accumulate substantially.

Durability directly affects replacement frequency. A robust light costing twice as much but lasting four times longer delivers better value than budget alternatives requiring frequent replacement. Factor in procurement time and administrative costs of repeated purchasing.

Warranty terms indicate manufacturer confidence in product longevity. Extended warranties on professional equipment suggest genuine durability. Limited or absent warranty coverage may signal anticipated failures.

Matching LED Work Lights to Specific Applications

Different industrial applications emphasise different performance characteristics. Matching equipment to actual use cases optimises both effectiveness and value.

| Construction & Civil Engineering High output, weather resistant, long runtime. Built to withstand demanding outdoor environments and rough handling. | Maintenance & Repair Compact, manoeuvrable, magnetic mounting. Focused beams for illuminating components within machinery or vehicles. |

| Inspection & Survey High CRI for accurate colour rendering, even light distribution. Quality illumination for reliable visual assessment. | Emergency Response Instant deployment, reliable operation. Extended runtime for unpredictable incident durations. Optional strobe modes. |

For extended-range inspection across large areas, dedicated searchlights provide the reach needed to examine distant structures or terrain.

Choosing LED Work Lights That Deliver

Effective LED work light selection balances multiple factors against specific operational requirements. Output specifications, battery performance, build quality, and practical features all contribute to real-world effectiveness.

Prioritise the characteristics that matter most for your applications. Inspection work demands quality illumination and portability. Construction sites need durability and weather resistance. Confined space operations require compact form factors and safe battery technology. Investing in properly specified industrial LED lighting pays returns through reliable performance, reduced replacement costs, and improved operational efficiency. The time spent understanding your requirements and matching them to appropriate equipment ensures those returns materialise.

For general workspace illumination, 1,000 to 3,000 lumens suits most tasks. Detailed inspection work may require higher output or focused beams. Consider beam pattern alongside lumen count, as a well-directed 1,500 lumen spot can outperform a diffused 3,000 lumen flood for close work.

IP65 or higher is recommended for most industrial environments. IP65 provides complete dust protection and resistance to water jets.

Runtime varies by output level and battery capacity. Professional units typically offer 4 to 12 hours on medium settings. Always check runtime at the brightness level you’ll actually use, as manufacturers often quote maximum runtime at lowest settings.

Yes, LED work lights are well-suited for confined spaces because they produce no emissions and generate less heat than halogen alternatives. For explosive atmospheres, ensure the light carries appropriate ATEX certification for the hazard zone.

Flood beams spread light across a wide area, ideal for general workspace illumination. Spot beams concentrate light into a focused pattern, better for detailed inspection, electrical work, and examining specific components.

Some units support pass-through charging, allowing operation during charging. Check individual product specifications, as this feature varies between models.